Since 1945 Architectural Grille has manufactured metal products of the highest quality with exceptional service.

We are able to offer custom and stock metal products with a limitless number of design possibilities. Using the latest in technology, it is now possible to cut integral and complicated shapes and design patterns in materials such as acrylic, wood, glass, marble and all metals.

Specializing in custom projects with no minimum quantities, Architectural Grille is able to consistently deliver high quality factory-direct products to a variety of markets including but not limited to residential, commercial/retail, industrial, architecture & design, hospitality, medical and education.

Architectural Grille is proud to be a member of the Green Council and support sustainability by offering recycled aluminum and sourcing reclaimed materials to fabricate our products.

By utilizing state of the art machinery incorporating CNC Punch, Laser and Waterjet technologies, we are able to offer extensive capabilities that include AutoCAD design, welding, bending, powder coating and finishing, all of which can be applied to areas of construction and interior design, including decorative screening, logos and artwork.

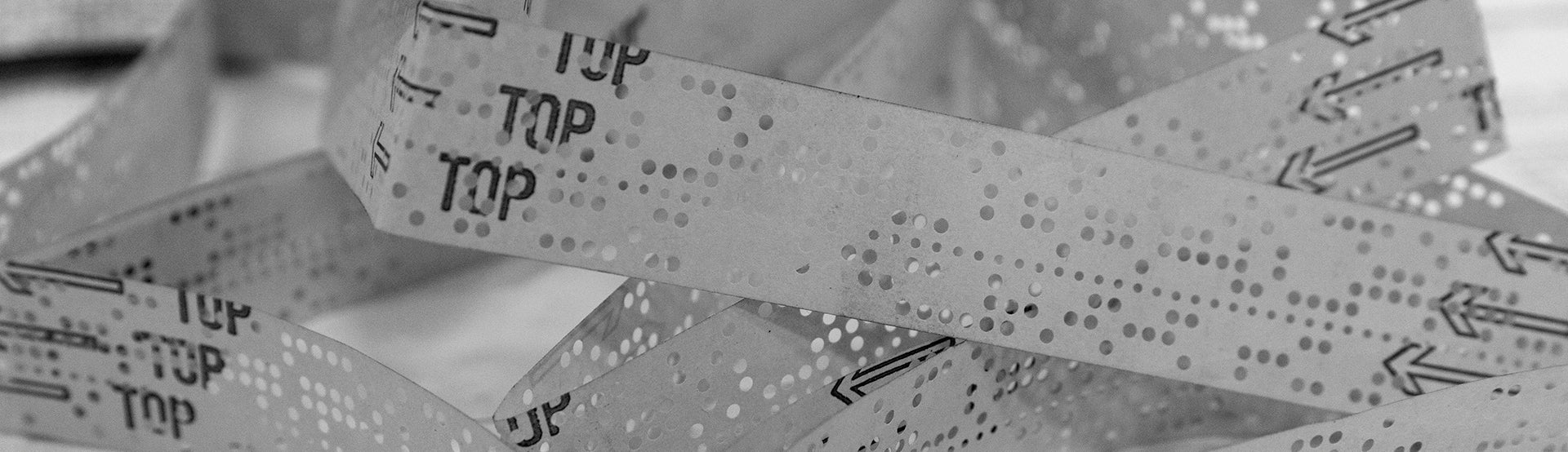

PERFORATING

Architectural Grille utilizes modern technology incorporating Laser, WaterJet and CNC Punches as part of our sheet metal manufacturing process to fabricate high quality perforated products. Perforated materials are very versatile ranging from lightweight decorative elements to load-bearing structural components, offering unique opportunities to combine strength, functionality and beauty. By using this technology we are able to perforate/cut light (0.03125”) to heavy (1”) gauge materials in widths up to 60” and 120” in length.

Perforated materials have many advantages and benefits as outlined below:

Acoustic Performance

Helps limit health effects from noise in the workplace & community, numerous studies have shown that perforated metals help reduce sound levels.

Weight Reduction

Lightweight perforated metal sheets are advantageous for the building structure when they are installed on the building.

Heat Dissipation

Buildings using perforated metal sheets in front of their façade can bring in substantial energy savings as a result of HVAC & lighting consumption reductions. Solar irradiation has also been shown to decrease significantly by using these products, depending on the location and positioning of the building, as well as the intensity of sun exposure.

Limited Maintenance

Depending on the finish applied, perforated products require limited cleaning providing cost savings. There is also the added benefit to the environment of not using detergents, energy or water to clean products as frequently.

Durability and Longevity

Long lasting and not needing to be replaced as often adds up to financial savings, while not creating new material and related waste/CO2 costs are also environmental benefits.

Versatility

Can be used in any location, interior or exterior applications. Be sure you choose the right alloy for stainless steel when being used near/in ocean-side (salt) or high traffic (pollution) atmospheres.

Green ProducT

Any excess metal leftover from the sheet metal manufacturing process, known as slugs, can be recycled to create new sheets and reduce waste.

Design Flexibility

Architects and interior designers are able to replicate, create and produce elements that are both decorative and functional.

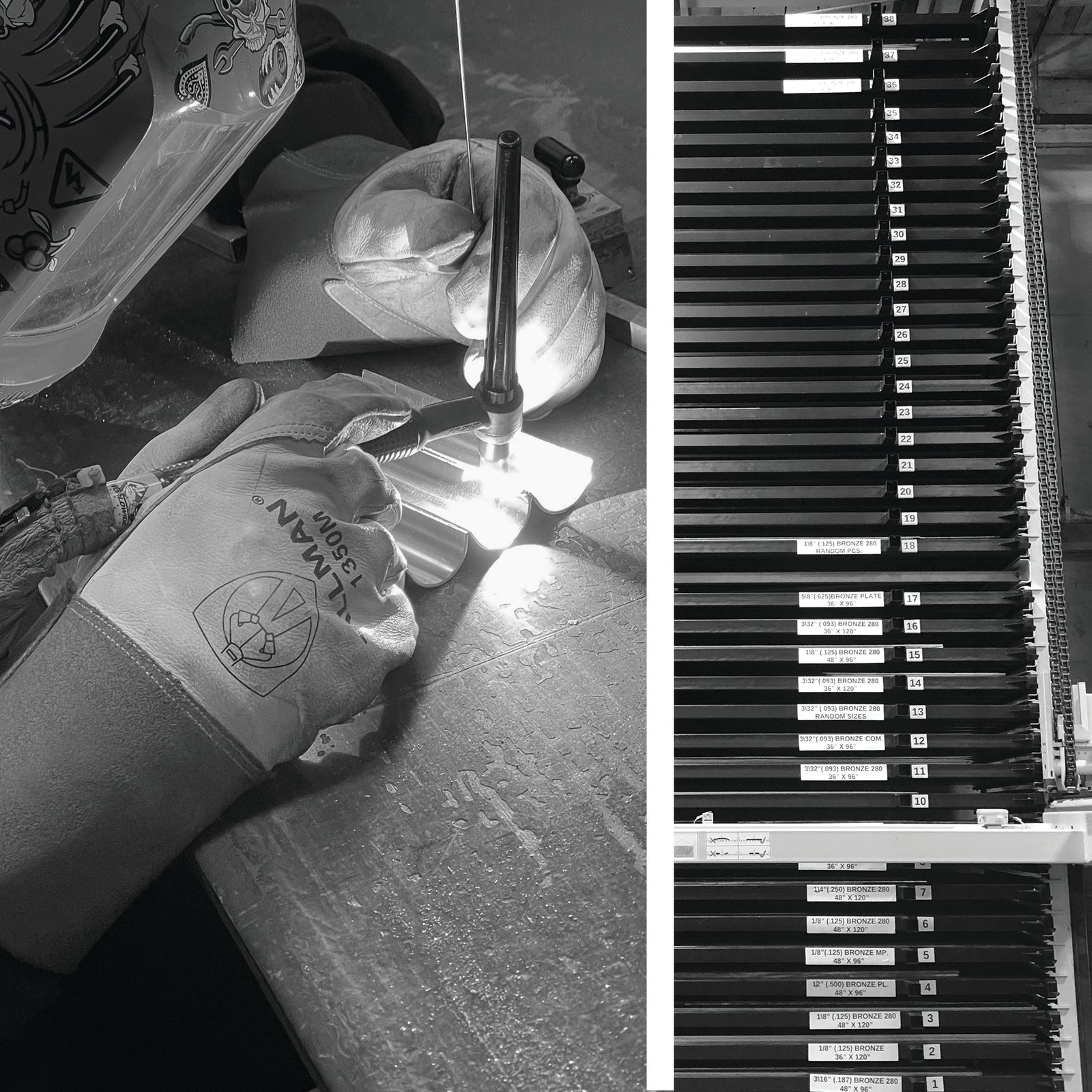

FABRICATION

Architectural Grille is a custom fabrication shop that uses cutting, punching, bending and assembling processes to produce quality products. Our fabrication capabilities are extensive, no matter if the project is large or small, we are able to fabricate your job in-house, resulting in reduced lead time caused by outsourcing, and increasing turnaround times for an on-time project delivery date to your job site. By employing highly skilled and trained workers and the latest in modern technology, Architectural Grille is proud to offer OEMs and contractors the following list of value-added metal fabrication processes:

PERFORATING

NOTCHING

LASER CUTTING & ETCHING

GRINDING

Our onsite equipment includes:

Shears

Cold Saws

Abrasive Band Saws

Plasma

Laser

CNC Punch

WaterJet

MATERIALS

we use post-consumer 94% recycled aluminum that allows you to potentially qualify for LEED certification

Brass

Bronze

Stainless Steel

Steel

Copper

ABS

Acrylic: Plexiglas, Lucite, PMMA

Paper

Stone

Glass

Cloth

Rubber

Wood & Wood Products: Reclaimed, Bamboo, MDF, etc

ARCH GRILLE sources the highest quality raw materials from vendors located within the USA

FINISHES

Satin

Mirror Polish

Statuary

LIGHT, MEDIUM, DARK

Primed

Anodized Colors

Clear, Black, Duranodic (Light, Medium, Dark)

Powder Coating

ANTI-MICROBIAL COATINGS

Architectural Grille is excited to now offer a line of anti-microbial powder coatings that inhibit the growth of bacteria, viruses, fungi and algae, and also prevent the development of odors, mildew and discoloration associated with these microorganisms.

We are excited to be able to offer our customers a product line that provides high temperature stability, color retention as well as long-term protection, most importantly it addresses an increasingly significant issue in the marketplace - a healthy lifestyle.

GREEN MATERIALS & PRODUCTS

Architectural Grille is proud to be a member of the U.S. Green Building Council and support sustainability by offering recycled aluminum and sourcing reclaimed materials to fabricate our products.

The LEED™ (Leadership in Energy and Environmental design) Rating System (http://www.usgbc.org/leed) was first developed in 1998 by the U.S. Green Building Council to promote design and construction practices that increase profitability, while reducing negative environmental impacts of buildings and improving occupant health and well-being. LEED™ certification is the recognized standard for measuring building sustainability.

Sustainability

Water

Efficiency

Energy

Atmosphere

Materials and Resources

Indoor Environmental Quality

Innovation of Design

Leveraged Local/Regional Materials Sources